PVC/Silicon dot coating machine for non-slip carpet

This dot coating machine can apply anti-slip plastic dot coating onto basic materials such as non-woven fabric, felt, etc., in dot form or other patterns, for anti-slip purposes.

It is widely used in the carpet industry, textile industry, home decoration industry, anti-slip fabric production, hotels, garments, gloves, sports products, and more.

Product features

The KUNTAI Silicon/PVC/plastic dot coating machine includes a base fabric unwinding device, dot coating device, needle plate raw material loading device, electric heating drying oven, automatic needle removal device, air cooling, and counting rewinding device. It is suitable for applying silicon/PVC dot coating onto nonwoven fabric, felt, fabric, and other materials for non-slip purposes. It is widely used in the sofa fabric industry, interlining for the cloth industry, shoe industry, outdoor goods, medical industry, mattress protector industry, curtain fabric industry, automotive trim industry, hygiene and medical products, protection clothing, and more.

The machine is easy to operate, with a wide gluing width, precise glue amount adjustment, and glue-saving features. Different conveyor systems can be chosen based on the type of basic material.

-

Main working process: hydraulic edge alignment for raw material feeding, screen dot coating, needle plate raw material loading, needle plate stenter moving to the electric heating drying oven for dot drying, automatic needle removal, air cooling, counting, and rewinding.

-

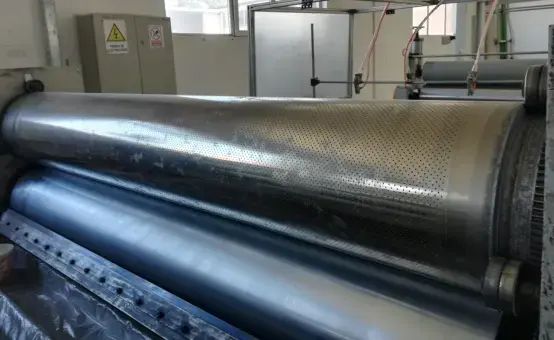

Roller to achieve different coating patterns.

-

Machine working width ranges from 1600 to 4600mm, meeting various width requirements.

-

The electric heating oven ensures even and fast drying of the plastic dot.

-

Needle plate type conveyor belt is available to fix the edge of the basic material and maintain consistent material widths after heating and drying.

-

A special tension control device and edge guiding device can be added for stretch fabric.

-

Transmission mode: frequency conversion synchronous control; PLC touch screen operation can be upgraded.

-

Chemical formula can be provided if needed.

Main Machine Parameters (Customizable)

Modell | KT-1800 |

|---|---|

Machine Roller Width | 1800-4800 mm |

Heating oven length | 15 m |

Machine speed | 5-20 m/min |

Power | 100-300KW |

Electric Current and Voltage | Customizable |

Net Weight | 11000 kg |

Dimension | 30000x4000x2100mm |

Transmission | Inverter |

Motor | Siemens |

Electric | Schneider |

Maximum Material Width | 1600-4600 mm |

Machine drawing & pictures

Application